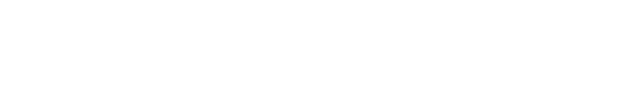

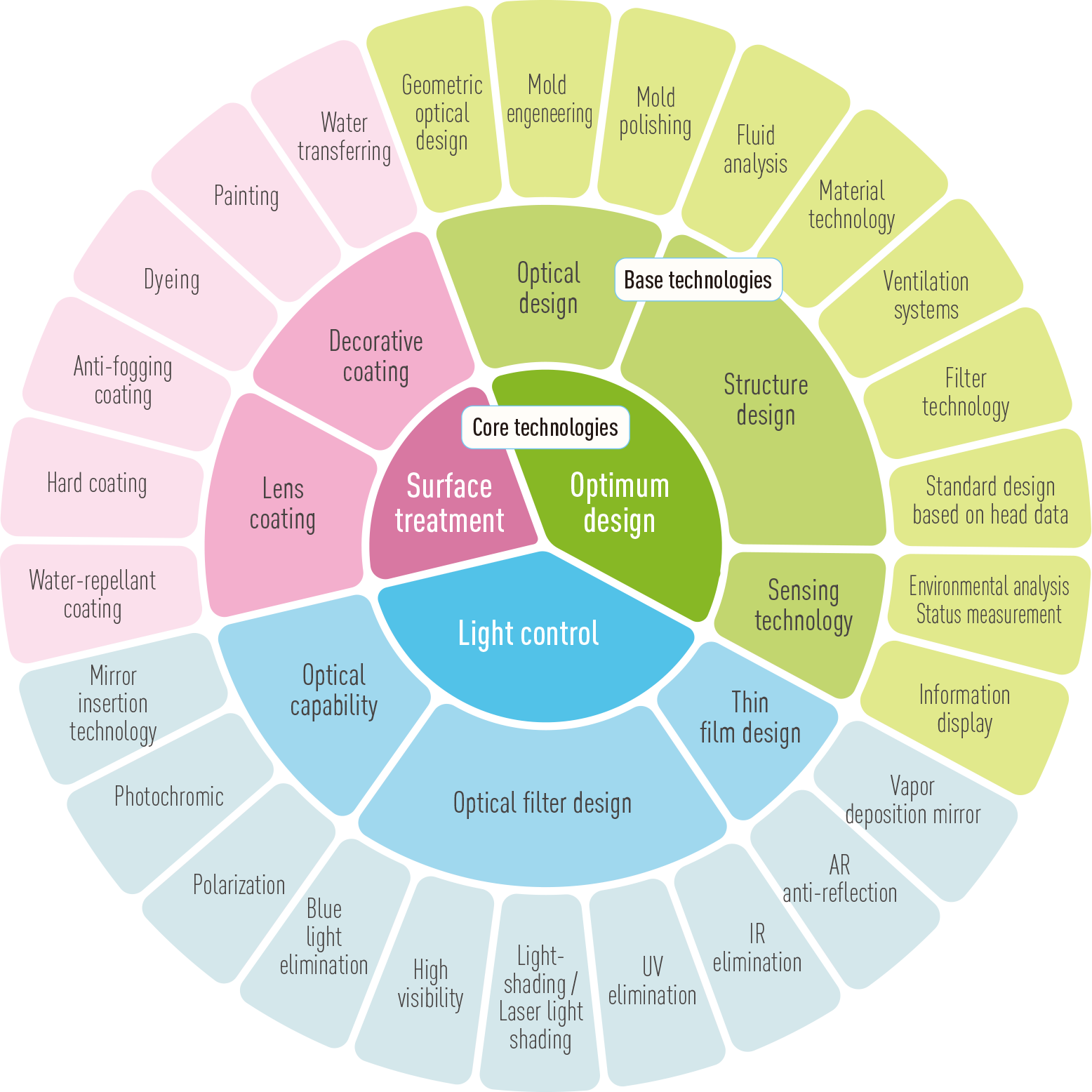

Yamamoto Kogaku has strived for over 110 years with the three technologies of light control, surface treatment, and optimum design at its core. We have combined these technologies in the integrated production of eyewear products at our own plant while continuing to pursue ever higher quality in safety and comfort as we move forward.

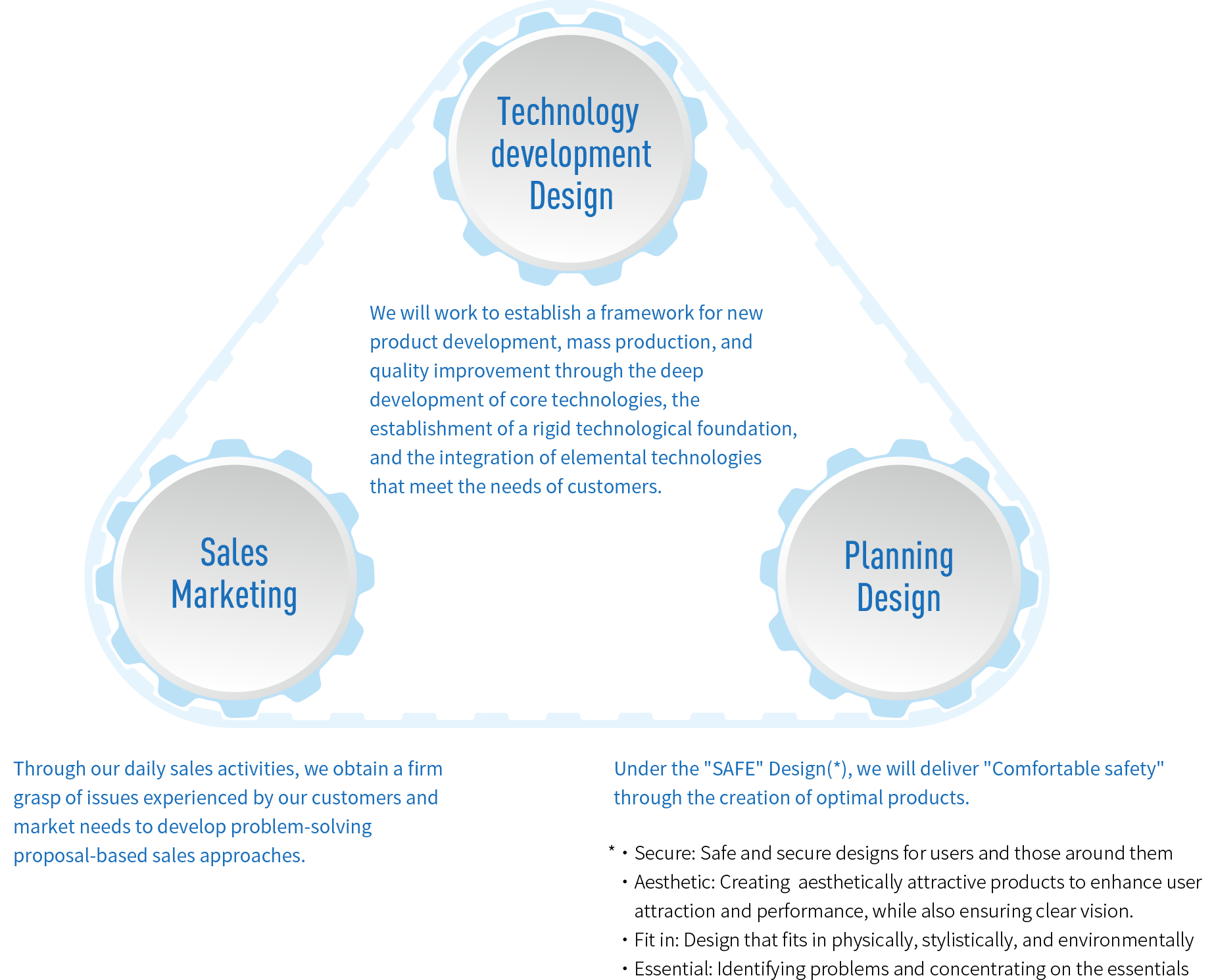

Yamamoto Kogaku has a firm handle on the needs of users and the value of technology, and we use all the power within us to provide information and services related to safe and comfortable products to the customer. Through strong ties between sales and marketing as well as planning and design, each member is able to exhibit their creativity, prowess in creating proposals, and ability to swiftly take action. This in turn allows us to optimize our existing business by integrating internal and external technologies, and to create new products and new businesses by incorporating cutting-edge technologies.